i have here a hub conversion kit for a Torana (i dont know what other Holdens have the same ...)

A front wheel hub set and a adapter plate for the rear.

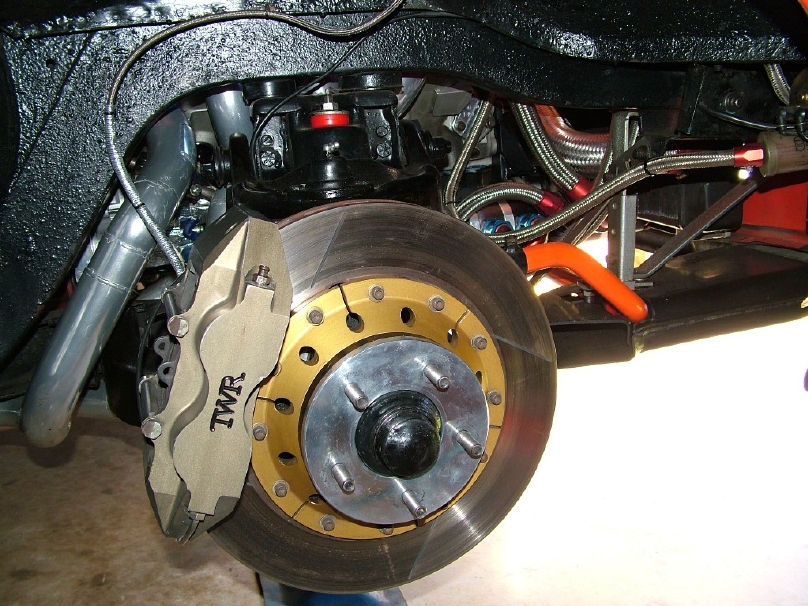

To use racing or other brake disc systems.

Made in Germany from 7075 Aluminium.

Both are made with BMW measurements PCD 5x120 to fit at the original PCD 5x108

This kit will be available with custom PCD`s soon at my Holden-Torana website

Anodized in Green,Red,Blue,Clear

%3Ca%20href=

"> %3Ca%20href=

"> %3Ca%20href= ">

">%3Ca%20href=

"> %3Ca%20href=

"> %3Ca%20href= ">

">Weight difference of the front hubs to original is minus 4,2 KG

Uwe

View Garage

View Garage