Anyhoo im sure someone out there has just the right ingredient.

Cheers,

Ken

Posted 22 December 2010 - 09:12 AM

Posted 22 December 2010 - 10:11 AM

Edited by Herne, 22 December 2010 - 10:23 AM.

Posted 22 December 2010 - 10:30 AM

Edited by ls2lxhatch, 22 December 2010 - 10:35 AM.

Posted 22 December 2010 - 12:22 PM

Posted 22 December 2010 - 12:40 PM

Posted 22 December 2010 - 05:44 PM

Posted 23 December 2010 - 04:53 AM

Posted 28 December 2010 - 09:42 PM

Autosol shouldn't scratch, what are you using to apply it?

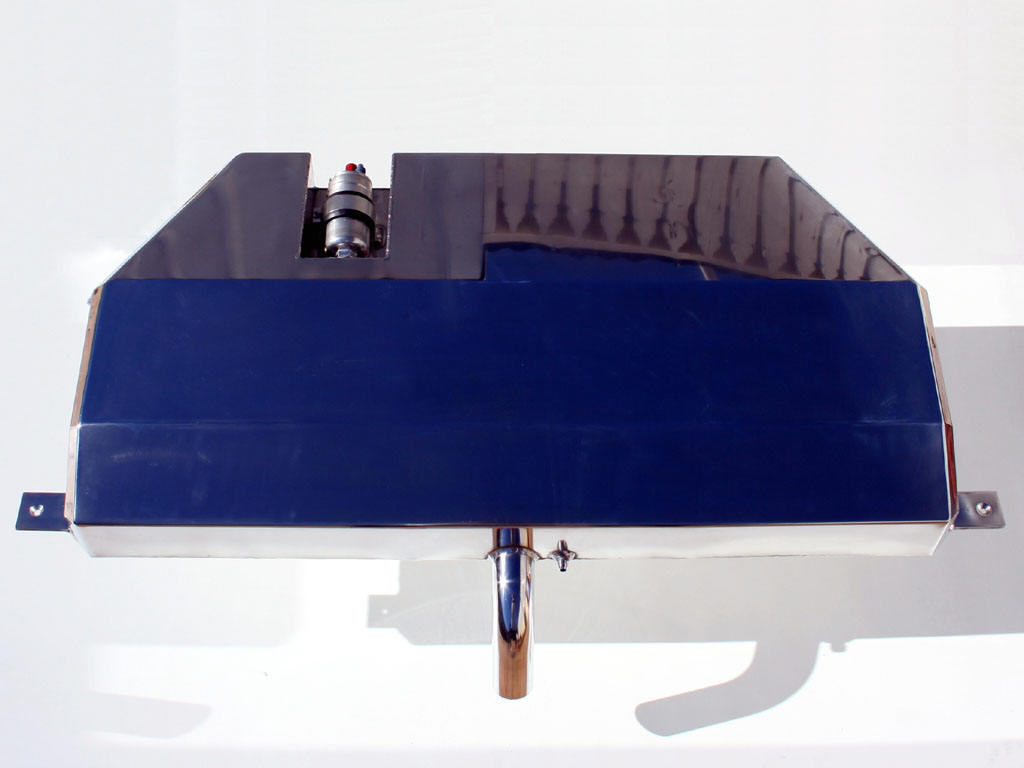

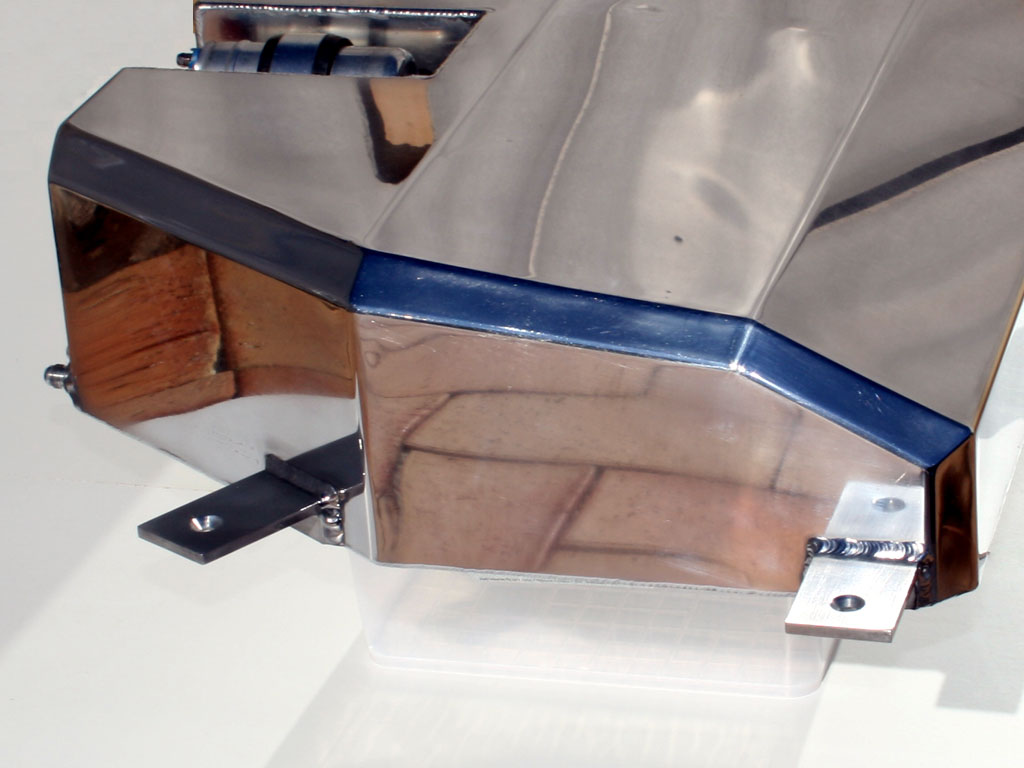

Mine's stainless, easy

Posted 28 December 2010 - 10:36 PM

Edited by ls2lxhatch, 28 December 2010 - 10:38 PM.

Posted 29 December 2010 - 06:55 AM

Posted 29 December 2010 - 07:15 AM

Posted 29 December 2010 - 07:53 AM

Posted 29 December 2010 - 08:41 AM

Posted 29 December 2010 - 08:47 AM

Edited by ls2lxhatch, 29 December 2010 - 08:50 AM.

Posted 22 January 2011 - 11:31 AM

You will often find Purple Polish in truck stops and truck parts suppliers.

I think I bought mine from Truckline.

Truckline Truck & Trailer Parts

10 Dobra Rd

Spearwood

WA 6163

08) 9434 1588

Posted 22 January 2011 - 12:23 PM

Posted 21 March 2014 - 10:38 PM

Autosol shouldn't scratch, what are you using to apply it?

Mine's stainless, easy http://www.gmh-toran...DIR#/tongue.gif

Posted 22 March 2014 - 04:51 AM

Autosol as mentioned, the stainless is pretty forgiving as long as its not damaged to begin with. It actually came with a protective film on it, I just scuffed up the very edges along the welds with scotch-brite

Posted 27 March 2014 - 06:04 PM

Can i ask who is making your stainless steel tank?

What grade of stainless steel are they using?

I know that 316 grade stainless steel WORK HARDENS as it flexes which means it loses its ductility and becomes brittle and eventually cracks.

I would be VERY careful using stainless steel for any kin of fuel tank.

I think this is the reason (other than cost of course) that people dont use stainless for tanks!

(Think of the weight of the fuel sloshing around under driving conditions and that cyclic loading against folds, sides, large flat areas, welds etc. these are the forces that will cause this work hardening and potentially lead to cracking!)

Posted 02 April 2014 - 11:55 PM

Posted 06 April 2014 - 06:03 PM

Cool mate!

All the best with it!

Posted 06 April 2014 - 06:28 PM

I know that 316 grade stainless steel WORK HARDENS as it flexes which means it loses its ductility and becomes brittle and eventually cracks.

I would be VERY careful using stainless steel for any kin of fuel tank.

I think this is the reason (other than cost of course) that people dont use stainless for tanks!

(Think of the weight of the fuel sloshing around under driving conditions and that cyclic loading against folds, sides, large flat areas, welds etc. these are the forces that will cause this work hardening and potentially lead to cracking!)

Hey Tiny? Alloy is much the same if not worse, If you fold it 90 degree (depending on the thickness and grade) it will split straight away thats why AFAIK its illegal to have any 90'bent sections in a alloy drop tank

I would not think the fuel sloshing around would cause any issues? you would actually have to be bending the stainless back and forth to make it crack. Every time you bend a material you are actually stretching the outside radius which in turn thins it out.

Posted 06 April 2014 - 06:38 PM

Hey Viper!

Fully agree with you mate, Alloy DOES do the same thing!

Alloy will do it differently though, (Depending on the alloy and more importantly the temper!)

I think that the fuel sloshing would actually cause small movements in the walling, and therefore small movements at the folds / welds which accumulate after time which is where the fatigue cracking would begin!

I'm concerned about the stainless as 316 grade can be very "brittle" straight off the bat, and I've not seen many tanks (especially large tanks in cars or boats) made from stainless, and the main reasons i can think of are cost, and fatigue cracking!

I'd be happy for someone with more knowledge than i to set me straight on it! but i just wanted to make sure that the knowledge and concerns i have were put out there!

Cheers! ![]()

Posted 07 April 2014 - 09:31 PM

Posted 07 April 2014 - 09:32 PM

you can get buffs for 9" grinder/polishers which shit all over a drill attachment, especially for large jobs you obviously cannot use a bench grinder for. I still dont know where to find such a thing but i do see the professionals use them for big jobs, especially things like diesel tanks for trucks.

0 members, 1 guests, 0 anonymous users