I think you will find that the SuperPro bushes can be turned down in a lathe. I have a couple of spares from an incomplete set to experiment with if you want. Personally I would just make a alloy bush for the top as well.

I am using this style of bush on the trailing arms. I have tubular trailing arms which I feel need either a soft bush or a bush that can pivot. I believe the factory arms will twist a bit under extremes of suspension movement whereas the tubular or boxed arms have no give at all and require either the bush or the mount to absorb the twisting movement.

Spot on Andy.

Even if using a bush that can pivot, you then introduce a differnet ype of bind whereby 3 of the trailing arms are trying to change the length of the 4th one so you still need a compliant bushing in there somewhere or you will crack something.

I plan to replace the top diff bushes with rubber when I get the hatch home even though I have the soft poly in there now and those same type of pivoting bushes in the top front of the trailing arms.

Also imo its definitely best to run pivot rod ends on your torque arm set-up rather than a poly bush.

Tie/ Pivot Rod Ends are a great idea, but can't use them. I have to keep within the rules. For anyone interested, this is a link to the rules for Improved Production.

http://docs.cams.com...29_Group_3J.pdf

The ruling for this is:

9.3 Bushes: Elastomeric bushes used at suspension pivot points (which are not otherwise specified in these regulations) may be replaced by other elastomeric bushings.

&

9.10 Rear suspension components: Devices for the lateral location of the rear wheels on vehicles with a live axle, and any associated brackets on the body, are free. Brackets may be welded to the body. All other components which have any function in the location of the rear wheels must be retained unmodified except for bushings, which must comply with 9.3 above. Drive flanges, trunnions, hubs, stub axles and wheel bearings are free. It is permissible to add additional longitudinal rear suspension arms provided that all bushings are elastomeric and that the mounting points on the body only involve the addition of metal, save for a single hole per arm of maximum diameter 25mm.

I can replace all rubber bushes with Superpro or nolethane as they are considered elastomeric, rod ends are not. Another point to note is that where it says: All other components which have any function in the location of the rear wheels must be retained unmodified except for bushings, means I cannot replace or modify the 4 trailing arms off the diff.

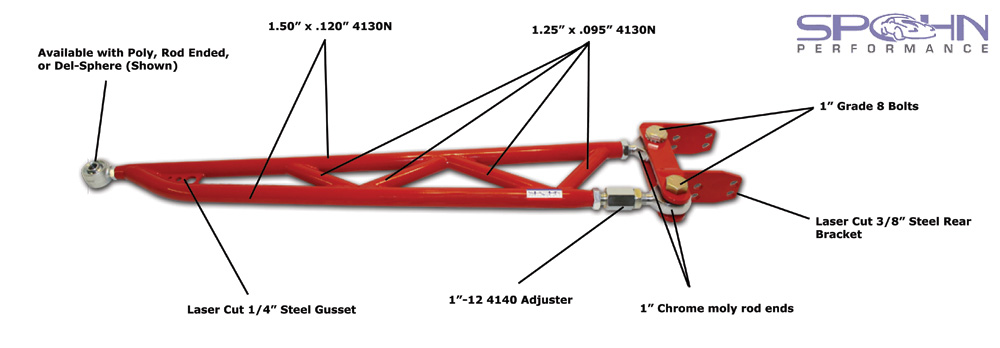

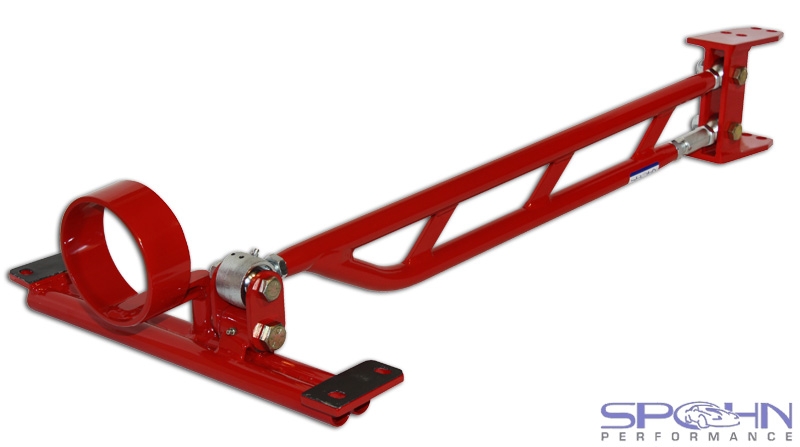

What I will be doing is making the 2 top arm virtually redundant, and going for a 3 link set up with a Torque Arm as LXSS350 posted. Although the picture he put up whilst it might be a good bit of kit, I cant use because of the Pivot Rod ends.

What I am considering using I what my mate who is building the Monaro I posted pictures of a few pages back suggested.

Torque Arm.jpg 121.54K

9 downloads

Torque Arm.jpg 121.54K

9 downloads

I should note that in this picture it is only the torque arm and not the other gear in the photo I plan to copy/ use.

Good fun Huh, building a car within rules!!!!!!

Edited by eyepeeler, 03 August 2013 - 03:44 PM.

View Garage

View Garage